Electrostatic Precipitator Audits

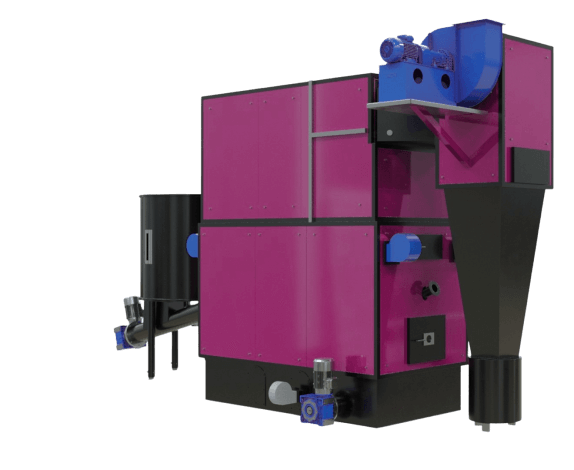

The advantages of these devices operating in standard mode include:

- achieving emission levels lower than those specified by regulatory requirements,

- low energy consumption, resulting in high efficiency,

- durable construction,

- customizable design,

- long service life,

- maximum flue gas volume capacity of up to 13,000 m³/h,

- as well as low maintenance requirements with favorable investment costs (limiting maintenance to one service visit per year).

Operating Principles

of Electrostatic Precipitators

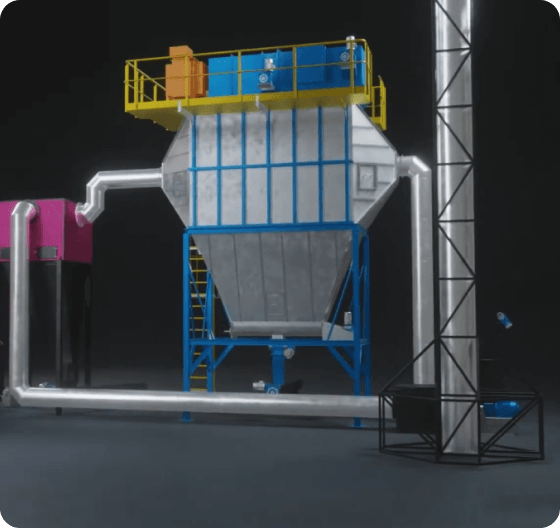

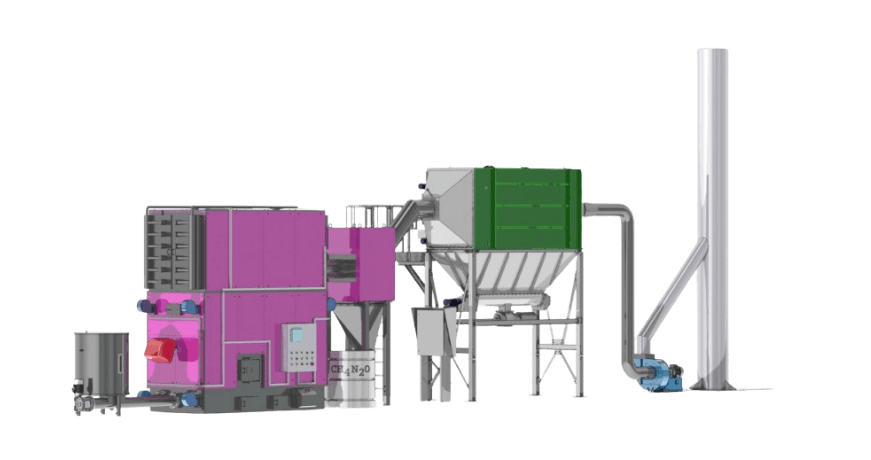

Process gases laden with dust enter the electrostatic precipitator horizontally. The incoming gas is evenly distributed across the entire filter surface at a uniform flow rate. Spark discharge electrodes located between the collecting plates create an electric field that imparts an electrical charge to dust particles. As the charged particles travel through the electric field, they are drawn by electrostatic forces to the collecting electrodes, where they agglomerate with previously collected particles and are removed via mechanical shaking. The dislodged dust layer falls into a collection hopper and is discharged through the dust outlet. The cleaned gas then exits the precipitator through the gas outlet casing.

Within the gas flow channels are centrally mounted frame assemblies fitted with knife‑edge steel strip electrodes. Depending on the model, channel spacing may vary, providing high flexibility of application.

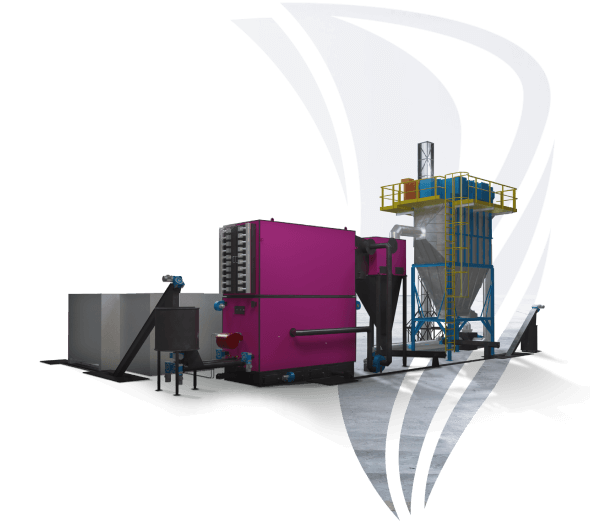

Available fuel feeding systems

Electrostatic precipitators by Beth

Compared to filter separators, Beth electrostatic precipitators offer very low energy costs thanks to the use of cutting‑edge high‑voltage control technology. These units deliver exceptional filtration performance.

Beth’s portfolio includes dry electrostatic precipitators for thermal waste combustion processes, as well as wet electrostatic precipitators designed for biomass boiler applications.

Free consultation with an expert

Want to know more about the solutions we offer?

Call +48 881 789 606 or write to us.