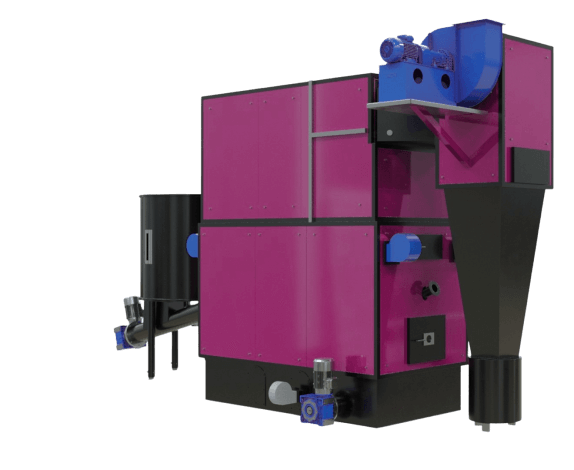

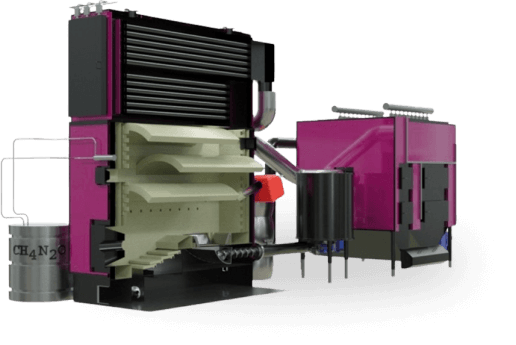

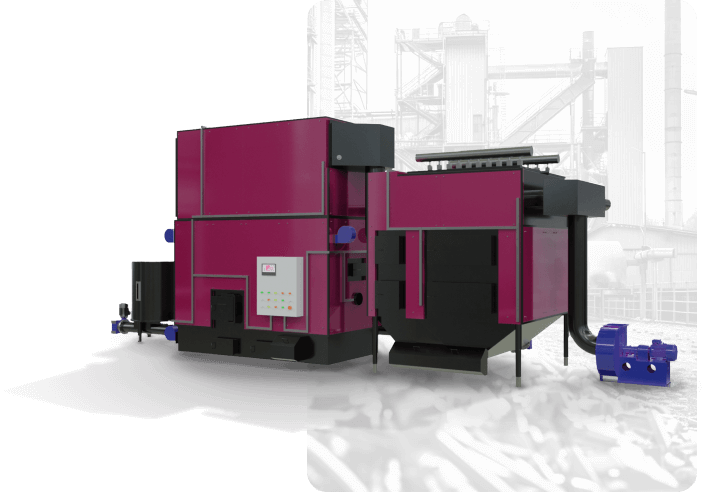

The Comfort Premium boiler is a modern, automatic, and maintenance-free heating unit – designed with the needs of today’s industry in mind. The boiler is adapted for the thermal processing of wood-based waste. This means that its fuel consists of wood-based waste without prior cleaning. This type of boiler is an excellent solution for facilities where the waste includes mixed materials such as MDF, HDF boards or other products with additives like glue, paint, or varnish.

The Comfort Premium unit thoroughly purifies flue gases and meets strict emission standards. Specialized filters – bag filters and electrostatic precipitators – ensure dust removal from flue gases at a level of 10 mg/m3. The boiler’s power range covers 350 kW – 5 MW, making it suitable for the heating needs of even the largest production facilities.

The COMFORT Premium boiler is:

Fuel Used

Thanks to the use of the latest technological solutions, the Comfort series heating boilers can be used to burn a wide range of fuels. This includes, among others, shredded wood-based waste:

Wood chips

MDF

HDF fiberboards

OSB structural boards

Technical parameters

We offer customization of device parameters by selecting a nominal power range from 505 to 5000 kW, including the following:

- Nominal power: 350 kW–5 MW

- Boiler efficiency: 90%

- Average fuel consumption: 76–1275 kg/h

- Minimum combustion chamber temperature: 850°C

- Particle residence time in combustion chamber: 2 s

- Technical data sheet

Free consultation with an expert

Want to know more about the solutions we offer?

Call +48 881 789 606 or write to us.