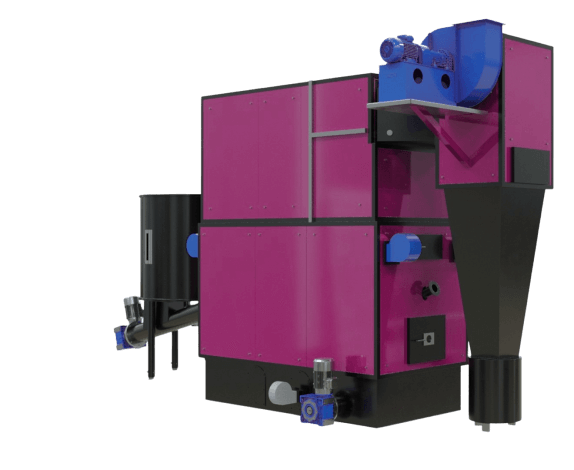

Advanced storage unit

The boiler-side container is an advanced storage unit that ensures efficient fuel storage and transport for industrial boilers. Equipped with moving scraper arms, the container enables continuous and smooth delivery of biomass and other bulk fuels. Thanks to its robust construction and reliable fuel transport systems, it is an essential component of modern heating installations, ensuring uninterrupted boiler operation and optimized combustion efficiency.

The containers are available in two capacities: 21 m³ and 40 m³, allowing the solution to be tailored to individual fuel storage and transport needs depending on the size of the installation and usage intensity.

Advantages of the boiler-side container

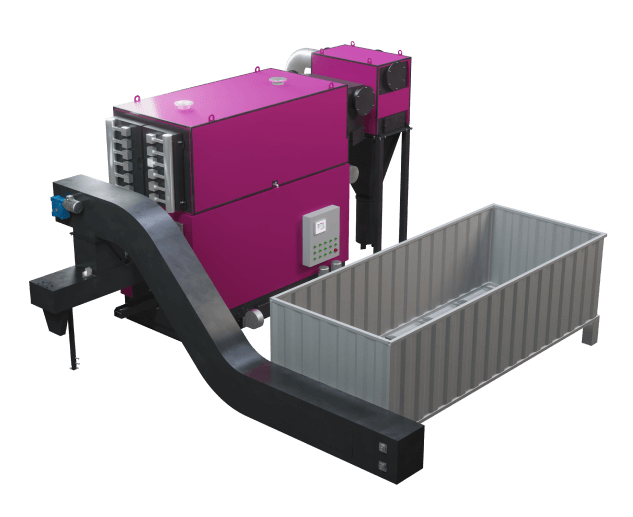

Fuel feeding systems – screw and redler conveyors

The boiler-side container can be paired with two types of feeders: screw or redler conveyors, offering full flexibility to adapt to the specifics of the installation and the type of fuel used.

Screw conveyor – ideal for precise feeding of biomass and loose fuels. It ensures a smooth flow of fuel into the boiler, minimizing the risk of blockages and ensuring efficient combustion. With controlled dosing, it is perfect for smaller installations that require accuracy in feeding shredded biomass.

Redler conveyor – an excellent solution for transporting larger quantities and larger-sized fuel over longer distances. This is a durable and efficient option that performs well even in heavily used industrial systems. Recommended for transporting wet and chunk biomass.

Applications

The boiler-side container with hydraulic scraper arms and a screw or redler conveyor is the perfect solution for industrial boiler rooms that require continuous fuel supply to the boilers. The automation of the fuel delivery process and the robust construction make this device a key component in minimizing downtime and enhancing the overall efficiency of the heating system.

Main specifications:

- Available capacities: 21 m³ and 40 m³

- Feeder type: screw or redler conveyor

- Scraping mechanism: hydraulically driven scraper arms

Investing in a boiler-side container with hydraulic scraper arms guarantees reliability, efficiency, and full control over the fuel storage and transport process, resulting in increased performance of the industrial boiler room.

Free consultation with an expert

Want to know more about the solutions we offer?

Call +48 881 789 606 or write to us.