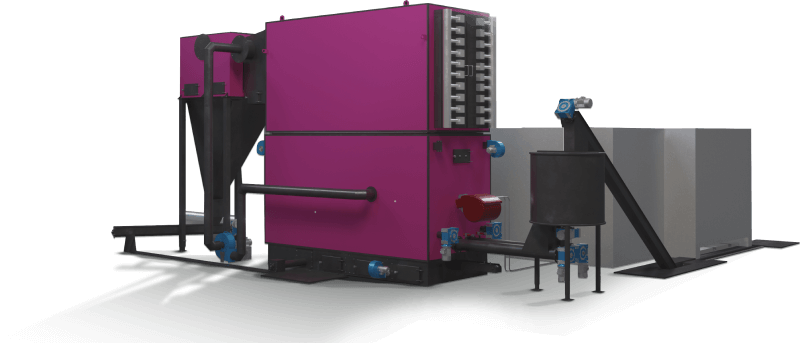

Central Heating Boilers powered by biomass perfect for industrial use

Heating devices in the COMFORT PREMIUM series are a combination of materials offering increased durability and modern technological solutions, which has allowed to increase the range of solid and fragmented fuels that can be used for combustion. Central Heating Boilers within the COMFORT PREMIUM series are modern devices whose design allows burning post-production waste, i.e. waste from particleboard and wood- based boards (HDF and MDF). An additional advantage of these boilers is that they can burn all kinds of forest biomass in accordance with the standards of the CLIMATE MINISTRY decree of September 24, 2020 on emission standards for certain types of installations, fuel combustion sources and waste combustion or co-incineration facilities, and the Decree of the Minister of Development of January 21, 2016, item. 108 on requirements for conducting thermal waste conversion (…).

The heating boilers are equipped with:

- ceramic furnace – its design ensures that the burned particles contained in the flue gases stay at a temperature of not less than 850°C at least 2 seconds after the last air supply

- ceramic ceiling – triple ceiling, which further ensures a long residence time of the fuel particle in conditions that allow it to burn completely

- uplift grate, supported by a settling (afterburning) grate – ensures proper combustion conditions and burning practically 99% of the material

- from 1500 kW power, the boiler is equipped with a moving grate as standard

- air blowing zones – they provide optimum conditions for conducting the process of thermal transformation of post-production waste

- oil burner – if needed, the oil burner guarantees an additional portion of energy to maintain a minimum temperature of 850 °C

- fuel feeding system – provides the right amount of fuel needed to achieve the rated power of the unit

- automatic ash removal as standard

- water temperature sensor

- exhaust gas cleaning system, i.e. ceramic filter that ensures compliance with emission standards, as specified in the Decree of the Minister of Environment dated 01.03.2018 on emission standards from installations. Ceramic filter keeps dust at 10 mg/m3

- temperature sensor – provides continuous measurement of the temperature in the combustion chamber

- temperature sensor – provides measurement of flue gas temperature

- Lambda probe – provides measurement of oxygen content in the exhaust gas

- exhaust fan – ensures adequate negative pressure in the combustion chamber

- safety thermostat

- thermostatic fire valve

At the customer’s request, the boilers can additionally be expanded with various useful functions, such as an Internet connection that allows remote control of the device’s parameters.

Central Heating Boilers COMFORT PREMIUM can be used in any production facility from various industries, including but not limited to:

- kilt plants

- greenhouses

- warehouses

- carpentry shops

- closed and open water systems

In order to ensure the complete safety of users of our equipment, heating boilers are equipped with countermeasures. The thermostatic fire valve plays a key role in safety. Such innovative protection is already a standard in the international heating equipment market. Its task is to completely cut off the fuel supply when the device reaches a temperature that exceeds the imposed limits. A similar task is performed by a safety thermostat, which breaks the circuit by disconnecting its power supply when the device overheats.

We have also ensured maximum convenience in the operation of our equipment. Thanks to the ceramic chamber, carrying out maintenance and cleaning operations is very easy. COMFORT PREMIUM has a clear, intuitive interface that allows you to efficiently select all functions and parameters. We encourage you to read the COMFORT PREMIUM technical sheet below. If you have additional questions about the COMFORT PREMIUM model, feel free to use our contact form. UNIWEX experts will be happy to advise and help select the best additional features.