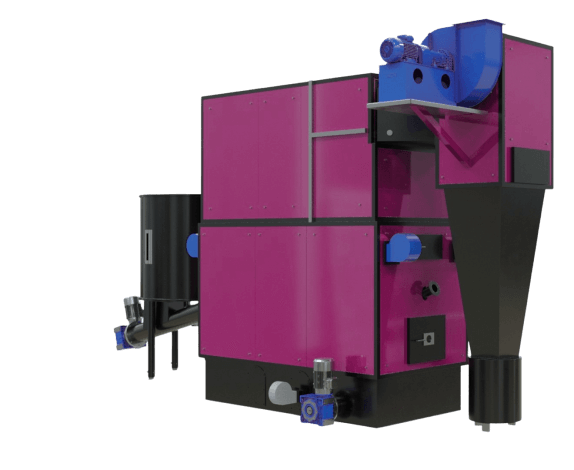

Flexible solution

for fuel feeding

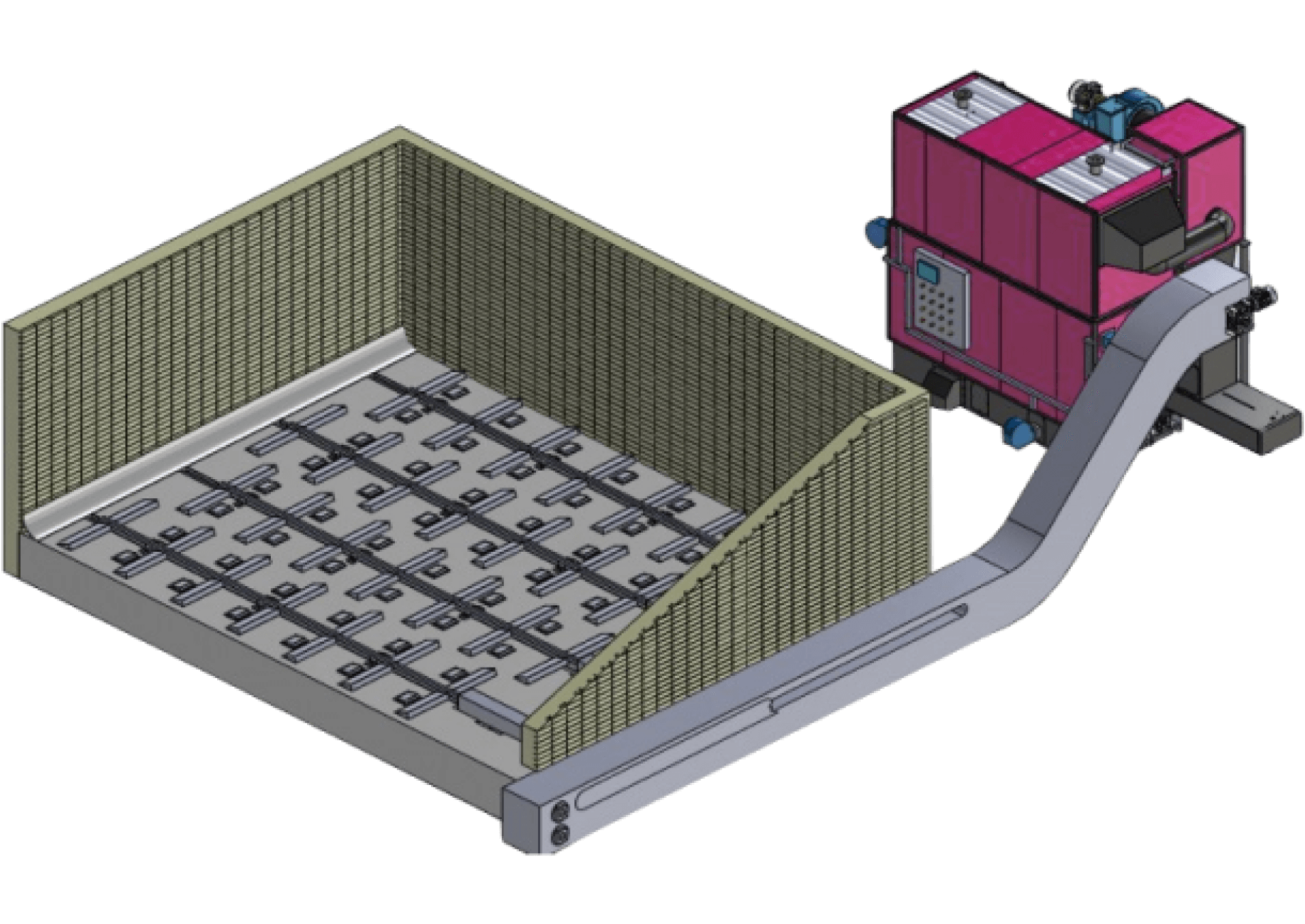

The moving floor with hydraulically driven scraper arms is an advanced system designed for transporting biomass and other bulk fuels. Thanks to the hydraulically controlled arms, fuel is effectively and evenly delivered to the feeders, ensuring continuous and reliable operation of industrial installations. This system is ideal for companies that require dependable fuel delivery solutions for boilers or other heating devices.

One of the key advantages of the moving floor system is its flexibility in adapting to the size of the available space. The system can be custom-designed to meet the client’s specific needs, allowing for optimal use of available room and enhanced system performance.

Advantages of the moving scraper floor

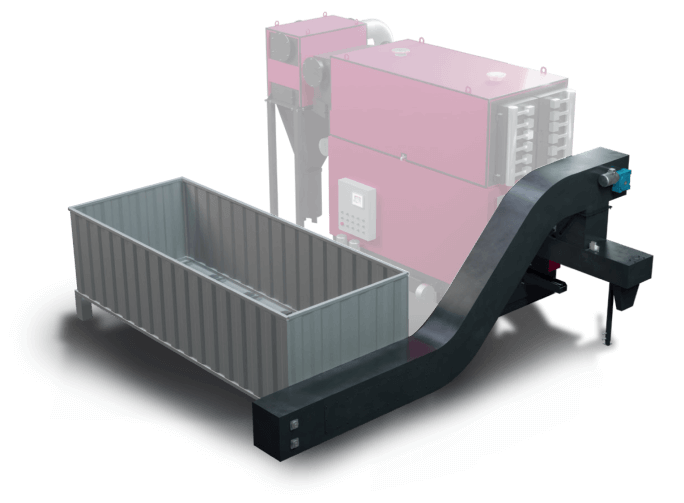

Fuel feeding systems – screw and redler conveyors

The moving scraper floor can be combined with two types of feeders: screw and redler conveyors, allowing flexible adaptation to the type of fuel and the specifics of the installation.

Screw conveyor – an ideal solution for transporting biomass and loose fuels. The screw conveyor offers precise fuel dosing, allowing for controlled material delivery to the boiler. Its design minimizes the risk of blockages and ensures smooth fuel flow, especially in smaller installations.

Redler conveyor – a durable transport system that performs excellently in industrial conditions where large quantities of fuel need to be moved over longer distances. Thanks to its robust construction, the redler conveyor is perfect for intensive applications requiring high capacity and reliability.

Advantages for the customer

Thanks to the moving floor with hydraulically driven scraper arms, your company gains a reliable, efficient, and flexible fuel transport solution. It’s an investment that ensures stable and safe boiler room operation for many years.

Free consultation with an expert

Want to know more about the solutions we offer?

Call +48 881 789 606 or write to us.